In today’s fast-paced logistics landscape, efficient warehouse operations can make or break a business’s bottom line. As e-commerce continues to surge and customer expectations for rapid delivery intensify, companies are turning to sophisticated technology solutions to optimize their warehouse processes. At the heart of this technological revolution lies the Warehouse Control System, a powerful tool that bridges the gap between warehouse management software and material handling equipment.

Understanding what makes an effective Warehouse Control System and identifying the essential features your business needs can transform your operations from reactive and chaotic to proactive and streamlined. This comprehensive guide explores the critical capabilities that modern warehouses require to remain competitive in an increasingly demanding marketplace.

Understanding the Role of a Warehouse Control System

Before diving into specific features, it’s important to understand what a Warehouse Control System actually does. Often confused with a Warehouse Management System (WMS), a Warehouse Control System serves a distinct and complementary function. While a WMS focuses on inventory management, order processing, and administrative tasks, a Warehouse Control System operates at the execution layer, coordinating and optimizing the real-time movement of materials and equipment throughout the facility.

Think of it as the conductor of an orchestra—the WMS provides the sheet music (orders and inventory data), but the Warehouse Control System ensures all the instruments (conveyors, sorters, automated storage and retrieval systems, and robotics) play in perfect harmony. This real-time orchestration is what enables warehouses to achieve maximum throughput, minimize bottlenecks, and respond dynamically to changing conditions on the floor.

Real-Time Equipment Integration and Communication

The foundation of any effective Warehouse Control System is its ability to seamlessly integrate with diverse material handling equipment. Modern warehouses deploy a wide array of automation technologies, from conveyor systems and automated guided vehicles (AGVs) to sortation systems and robotic pick-and-place units. Each piece of equipment speaks its own language, uses different communication protocols, and operates with unique parameters.

An essential feature of a robust system is its capability to communicate with all these disparate technologies through a unified interface. This means supporting multiple communication protocols such as Modbus, OPC UA, Ethernet/IP, and proprietary manufacturer protocols. Without this multilingual capability, businesses face the nightmare of creating custom integrations for each new piece of equipment, resulting in inflated costs and extended implementation timelines.

Beyond simple connectivity, the system must facilitate bidirectional communication that provides real-time status updates from equipment and sends dynamic control instructions back. This constant dialogue enables the system to monitor equipment health, identify malfunctions before they cause downtime, and make split-second decisions about routing materials to alternate paths when disruptions occur.

Intelligent Task Prioritization and Workload Balancing

Not all orders are created equal. Some require expedited handling for next-day delivery, others contain fragile items needing special care, and some might be bulk orders that can afford longer processing times. A sophisticated Warehouse Control System must incorporate intelligent task prioritization algorithms that consider multiple factors simultaneously.

This feature examines order priority, customer service level agreements, product characteristics, current equipment utilization, and downstream capacity constraints to make optimal decisions about which tasks to execute and in what sequence. The system continuously recalculates priorities as new orders arrive and conditions change, ensuring that high-value or time-sensitive orders receive appropriate attention without completely starving lower-priority work.

Equally important is workload balancing across multiple zones and equipment paths. Without intelligent balancing, warehouses experience feast-or-famine scenarios where some areas become overwhelmed while others sit idle. Advanced systems monitor utilization across all resources and dynamically distribute work to maintain optimal throughput while preventing bottlenecks from cascading through the facility.

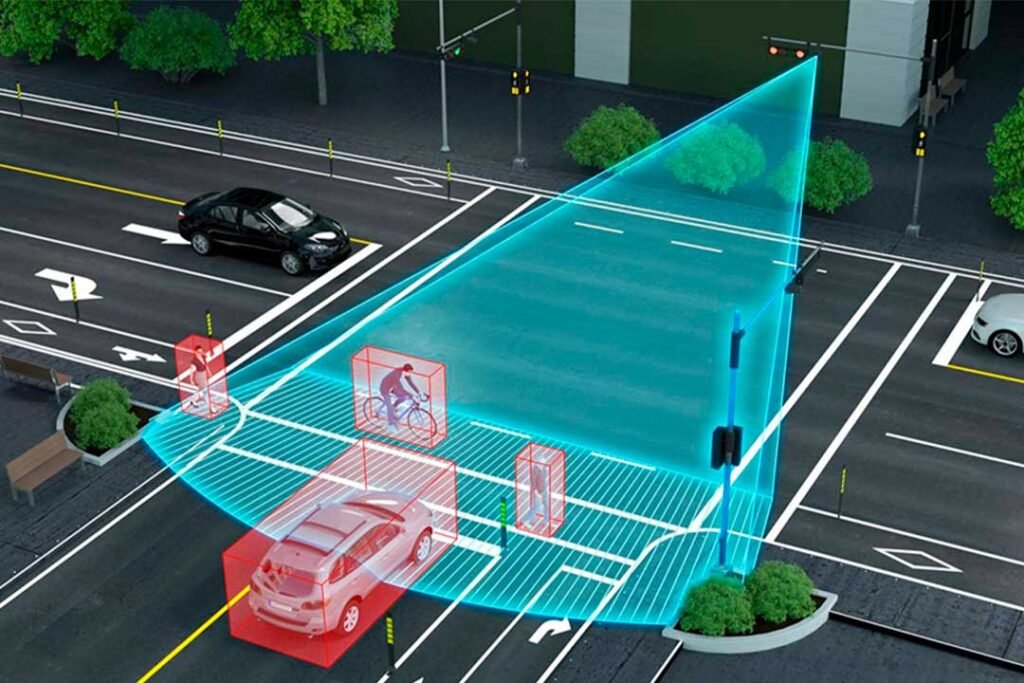

Dynamic Path Optimization and Traffic Management

In facilities with complex material handling networks, the path a product takes from receiving to shipping can significantly impact overall efficiency. A Warehouse Control System should feature dynamic routing capabilities that calculate the most efficient path for each item based on current conditions rather than relying on static, predetermined routes.

This optimization considers factors such as current equipment availability, congestion levels at various points in the system, energy consumption, and predicted future demand. If a primary conveyor line experiences a jam or scheduled maintenance, the system automatically reroutes materials through alternative paths without human intervention, minimizing disruption to operations.

For facilities employing mobile robotics or AGVs, sophisticated traffic management becomes critical. The system must coordinate the movement of multiple autonomous vehicles, preventing collisions, managing intersection priority, optimizing travel paths, and ensuring vehicles don’t deadlock each other. Think of it as an air traffic control system for your warehouse floor, constantly monitoring positions and orchestrating safe, efficient movement.

Comprehensive Analytics and Performance Monitoring

You can’t improve what you don’t measure. Essential analytics capabilities transform raw operational data into actionable insights that drive continuous improvement. A robust Warehouse Control System captures detailed performance metrics across every aspect of warehouse operations, from individual equipment utilization rates to order cycle times and system-wide throughput.

Real-time dashboards should provide at-a-glance visibility into current operations, displaying key performance indicators such as orders processed per hour, equipment availability, error rates, and bottleneck locations. Alert systems notify operators and managers immediately when metrics fall outside acceptable ranges, enabling rapid intervention before minor issues escalate into major problems.

Historical analytics reveal longer-term trends and patterns that inform strategic decisions. By analyzing data over weeks or months, businesses can identify recurring bottlenecks, understand peak demand patterns, evaluate the return on investment from automation equipment, and make data-driven decisions about where to allocate capital for future improvements.

Exception Handling and Problem Resolution

Even the most well-designed warehouse operations encounter unexpected situations. Products may be mislabeled, equipment can malfunction, items might fail quality checks, or orders may need to be cancelled mid-processing. How a Warehouse Control System handles these exceptions often determines whether they remain minor hiccups or escalate into operational nightmares.

Effective exception handling requires the system to detect anomalies quickly, pause or reroute affected work, alert appropriate personnel with sufficient context to resolve the issue, and seamlessly resume normal operations once resolved. The system should maintain a detailed audit trail of all exceptions, capturing what happened, when, how it was resolved, and how long resolution took.

Advanced systems incorporate machine learning algorithms that recognize patterns in exceptions and proactively suggest or implement preventive measures. For example, if a particular product consistently triggers sortation errors, the system might flag it for label redesign or dimensional verification before the problem multiplies.

Seamless WMS Integration and Synchronization

While a Warehouse Control System operates independently at the execution layer, it must maintain tight integration with the WMS that provides order information and inventory data. This integration should be bidirectional and near-instantaneous, with the WMS sending pick lists and order details while receiving real-time updates on task completion, inventory movements, and order status.

The interface between systems must be robust enough to handle high transaction volumes without creating bottlenecks. In high-velocity warehouses processing thousands of orders daily, even slight delays in data synchronization can cause confusion, duplicate work, or missed shipments.

Look for systems that support standard integration protocols and offer pre-built connectors for popular WMS platforms. This dramatically reduces implementation complexity and ensures that future upgrades to either system don’t break critical data flows.

Scalability and Flexibility for Future Growth

Business needs evolve, and your warehouse technology must evolve with them. An essential feature of any Warehouse Control System is architectural scalability that accommodates growth without requiring complete system replacement. This means the software should handle increased transaction volumes, additional equipment, and expanded facility square footage without performance degradation.

Flexibility is equally important. As new material handling technologies emerge and operational strategies shift, the system must adapt without extensive custom development. Modular architecture with configurable rule engines allows businesses to adjust workflows, modify prioritization logic, and integrate new equipment types through configuration rather than programming.

Cloud-based or hybrid deployment options provide additional flexibility, allowing businesses to start with on-premises systems for data security and migrate to cloud infrastructure as needs change, or vice versa. This deployment flexibility ensures the system aligns with corporate IT strategies and budget constraints.

User-Friendly Interfaces and Accessibility

Even the most powerful system provides little value if warehouse staff can’t use it effectively. Intuitive user interfaces that require minimal training enable faster adoption and reduce costly errors. Modern systems should offer role-based interfaces that present relevant information and controls to different users—operators see equipment status and immediate tasks, while managers access analytics and system-wide controls.

Mobile accessibility has become increasingly important as warehouse workers move throughout facilities rather than remaining stationed at fixed workstations. Tablet and smartphone interfaces allow supervisors to monitor operations, respond to alerts, and make adjustments from anywhere in the warehouse, improving responsiveness and reducing time wasted walking to control rooms.

Customizable dashboards let users arrange information according to their preferences and priorities, ensuring critical data remains visible while less important details don’t create visual clutter. This personalization improves situational awareness and helps staff make better decisions faster.

Conclusion

Implementing a Warehouse Control System represents a significant investment, but selecting one with these essential features ensures that investment pays dividends through improved efficiency, reduced operating costs, and enhanced customer satisfaction. The right system transforms warehouse operations from a source of frustration and unpredictability into a competitive advantage that enables businesses to meet increasingly demanding customer expectations.

As you evaluate options, prioritize systems that excel in real-time equipment integration, intelligent task management, dynamic optimization, comprehensive analytics, robust exception handling, seamless WMS integration, scalability, and user-friendly design. These capabilities form the foundation of warehouse operations that don’t just meet today’s challenges but adapt and thrive as your business grows and the logistics landscape continues evolving.

The warehouses that will succeed in the coming decade won’t be those with the most equipment or the largest footprints—they’ll be those with the smartest systems orchestrating every movement, decision, and task with precision and intelligence. Investing in a comprehensive Warehouse Control System with these essential features positions your business for sustained success in an increasingly automated future.